For skincare manufacturers, the quest for efficiency and quality is never-ending. Enter the Vippai VPD300E Eye Patch Making Machine, an innovation in the world of automated production. This advanced sealing and cutting machine not only streamlines the manufacturing process but also elevates product quality, making it an essential asset for any business focused on eye patch production.

Speed and Precision Redefined

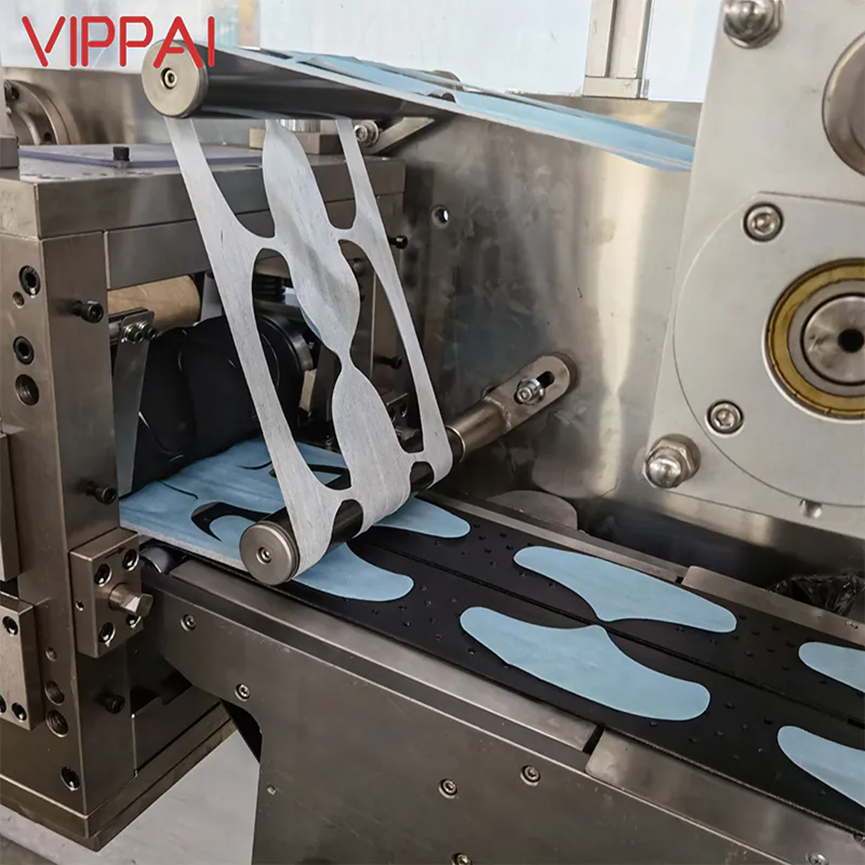

Imagine producing eye patches at a remarkable speed of 80-120 bags per minute. The VPD300E makes this a reality, allowing manufacturers to keep pace with high demand without sacrificing quality. Its cutting-edge four-side sealing technology ensures that each eye patch is sealed securely, protecting against contamination and ensuring freshness. This remarkable sealing and cutting machine enhances production efficiency while maintaining the integrity of the product, a crucial factor in today’s competitive market.

Customization for Market Versatility

Another advantage of the Vippai sealing and cutting machine is its ability to accommodate various types of eye patches. Designed specifically for non-woven materials, the VPD300E allows for extensive customization options, enabling businesses to respond swiftly to changing consumer preferences. This flexibility is vital in an industry where trends can shift overnight, ensuring that manufacturers can stay ahead of the curve.

Conclusion

In summary, the Vippai VPD300E Eye Patch Making Machine represents a powerful solution for businesses looking to optimize their production capabilities. With its high-speed performance and innovative sealing technology, this sealing and cutting machine not only boosts efficiency but also guarantees product quality. Elevate your eye patch production today by investing in the Vippai sealing and cutting machine and watch your business thrive!